Rapid Prototype Design, Fabrication, and Test at Stone Aerospace

In order to move fast on product design and development we’ve developed some rules and methods at Stone Aerospace that are different from traditional large aerospace concerns.

- Rule #1: nothing is impossible (unless it violates the laws of physics)

- Rule #2: bend the laws of physics if you can

- Rule #3: brainstorm it, build it, and get it out into the field for test as rapidly as possible (you only truly learn if it works by testing it in the real deal)

- Rule #4: design it as if your life depended on it (many of our products are, in fact, for manned systems and our staff are personally involved in field testing and use of our designs in extremely hazardous environments)

- Rule #5: Get the customer what they want in the least possible time for the best price

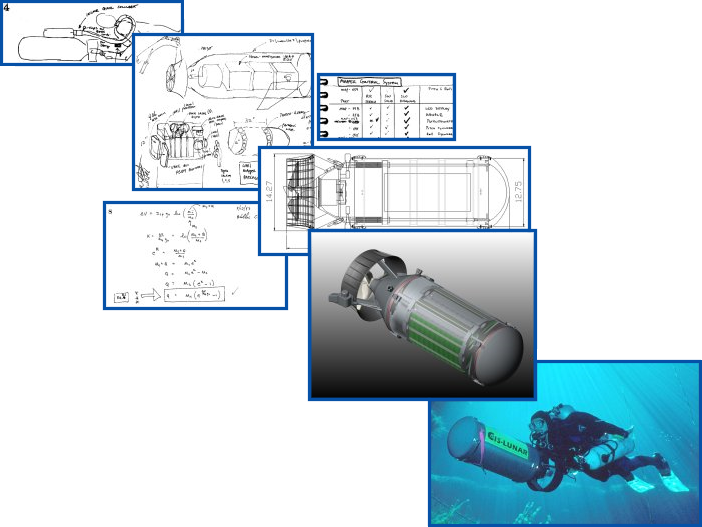

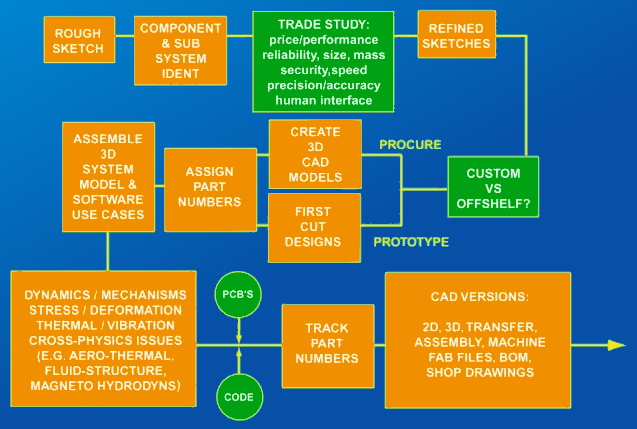

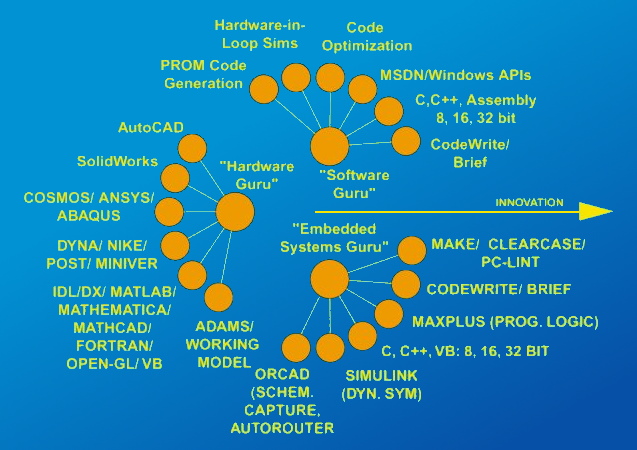

We work in a paperless design environment. Our native, “in-house” preference for mechanical design is SolidWorks for 3D and AutoCAD for 2D, but we can convert to and from just about any digital format. For analysis we generally use Cosmos (for stress, non-linear, dynamics, CFD, and mechanical dynamics) but have experience with many other codes. We can export to any rapid prototyping fabrication format. Similarly, we use OrCAD, VHDL, MatLab, SPICE and Simulink for digital embedded system design. We have complete in-house embedded systems software and firmware development tools. Our prototyping procedure generally follows the flow path shown here:

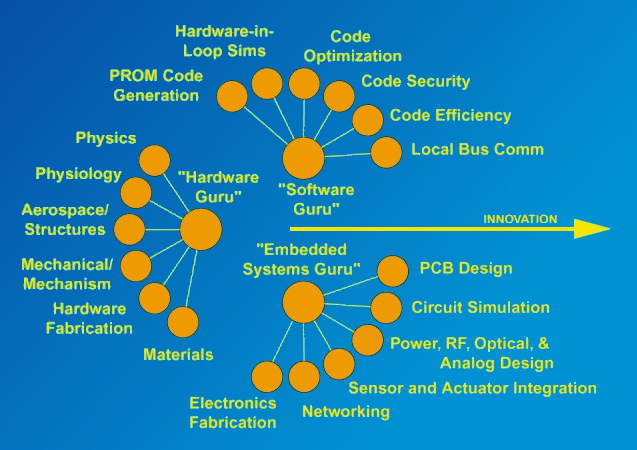

We organize our projects differently from the traditional aerospace industry. Rather than having a “standing army” of permanent staff, with their ponderous hierarchy of corporate business branches, divisions, and groups we run things more like a “Mission Impossible” episode. The designated project leader (always an extraordinary multidisciplinarian) examines a portfolio of truly virtuoso experts in our world-wide network. We typically select three individuals from this network—a “hardware guru”, a “software guru”, and an “embedded systems” guru to lead the team. These are world-class experts with decades of real-world design experience with concepts that have been turned into hardware that has gone into the field and been used hard. They then, when needed, call in a second layer of support staff from a wide variety of disciplines. This is illustrated in the figure here:

It is this architecture that allows us to move incredibly fast with respect to traditional business organization. There is no dead wood. We empower each expert to make instantaneous decisions and can bring on and release staff as needed. They select systems and sub-systems, perform component acquisition, and order fabrication by themselves. The majority of the design work is done at distributed design offices. We use high speed internet for regular teleconferences. When face-to-face meetings are needed, in particular during the systems integration and debug phase, we use the Armadillo Works facilities to house the team on-site for significant periods of time.

One of the reasons a small team like this is able to move incredibly fast is through the use of a wide variety of professional digital productivity tools. We are also fluent in both scientific software development as well as sophisticated proprietary visualization code. We can thus develop Windows or Linux software for a broad range of turnkey applications from system simulation. This includes training simulators, data visualizers, 3D map building tools, mobile data collectors, machine and vehicle field programming interfaces.

For a quote on a custom design, contact us.

DEPTHX Rapid Prototype Timeline

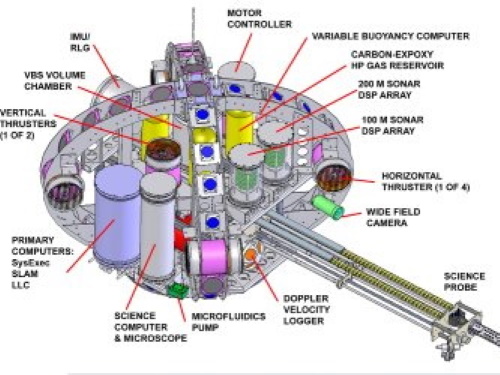

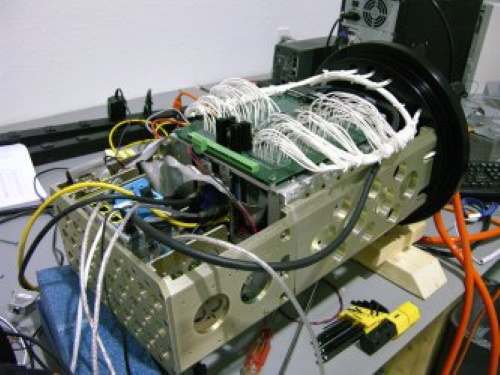

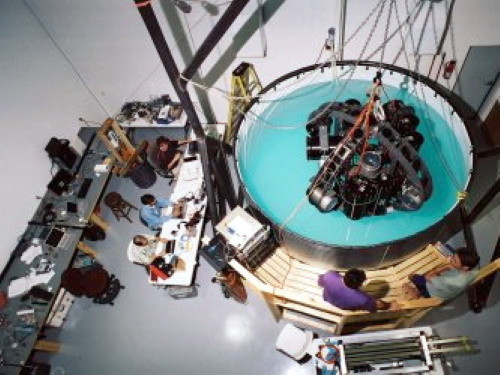

Probably the best way to show how fast we move on complex projects is illustrated by the DEPTHX vehicle. We froze vehicle computational architecture in October of 2005. We froze hardware designs in January of 2006 with the 4DOF AUV configuration shown here. The images that follow chronicle the manufacture, assembly and deployment of the vehicle – in 8 months flat.